UV-resistant marine ropes represent a significant advancement in maritime operations, offering enhanced durability and longevity that traditional boat ropes lack when exposed to harsh marine conditions and UV radiation. These advanced ropes are engineered with polymer technology that safeguards against UV degradation, preserving their mechanical integrity and maintaining consistent tensile strength and elongation properties essential for safety and functionality across a range of maritime applications. The resistance to environmental factors extends the lifespan of these ropes, leading to reduced maintenance costs and increased operational efficiency for maritime stakeholders. This technology is a testament to the strides made in materials science within the maritime industry, designed to meet rigorous standards. The deployment of UV-resistant marine ropes enhances mooring safety and efficiency by protecting against ultraviolet radiation, ensuring consistent performance across different maritime contexts. These coatings also play a crucial role in safeguarding the durability and functional integrity of boat ropes, combating seawater’s corrosive effects and environmental stressors, which are vital for both luxury yacht operations and commercial fishing practices. The environmental impact is reduced as these ropes require less frequent replacement, thereby contributing to ecological preservation. In summary, UV-resistant marine rope technology is a game-changer in the nautical industry, offering enhanced safety, longevity, and performance for maritime vessels of all kinds.

Navigating the maritime domain necessitates robust and resilient equipment, with marine ropes playing a pivotal role in daily operations. This article delves into the transformative advancements in UV-Resistant Marine Rope technology, highlighting its critical function in enhancing durability and performance within boat rope applications. We explore the significant contributions of these coatings to mooring efficiency and safety, emphasizing their chemical resistance properties that safeguard against the corrosive effects of seawater and environmental factors. Through case studies, we illustrate real-world scenarios where these technological strides have made a tangible difference, underscoring the importance of such innovations in maintaining operational integrity at sea. Join us as we unravel the intricacies of modern rope coating technology designed for marine applications.

- Understanding the Role of UV-Resistant Marine Rope in Maritime Operations

- Advancements in Boat Rope Coating Technologies for Durability and Performance

- Evaluating the Impact of Rope Coating on Mooring Efficiency and Safety

- The Importance of Chemical Resistance in Marine Rope Coatings

- Case Studies: Real-World Applications of UV-Resistant Marine Rope Solutions

Understanding the Role of UV-Resistant Marine Rope in Maritime Operations

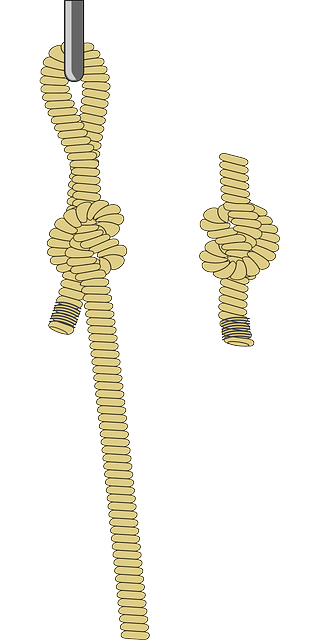

UV-resistant marine rope plays a pivotal role in maritime operations, offering unparalleled durability and longevity in harsh marine environments. Exposure to the sun’s ultraviolet rays can rapidly degrade traditional boat ropes, leading to fading, chalking, and ultimately, failure. However, UV-resistant marine ropes are engineered with advanced polymer technology that effectively blocks out harmful UV radiation. This protective feature ensures that the rope maintains its mechanical properties, such as tensile strength and elongation, even after prolonged exposure to direct sunlight. The resilience of these ropes contributes significantly to the safety and functionality of vessels, where they are used in a variety of applications including rigging, mooring, and fender ropes. Their ability to withstand environmental factors not only extends their lifespan but also reduces the need for frequent replacements and maintenance, which translates to cost savings and operational efficiency for maritime stakeholders. The integration of UV-resistant technology in marine rope manufacturing is a testament to the ongoing innovation in materials science tailored specifically for the demanding conditions found at sea.

Advancements in Boat Rope Coating Technologies for Durability and Performance

Evaluating the Impact of Rope Coating on Mooring Efficiency and Safety

In evaluating the impact of rope coating on mooring efficiency and safety in marine applications, it is clear that advancements in UV-resistant coatings for boat rope have significantly enhanced performance. These coatings are engineered to withstand the harsh environmental conditions encountered at sea, such as intense ultraviolet radiation, which can degrade uncoated ropes over time. By protecting the core material of the marine rope from UV penetration, these coatings extend the lifespan of the rope, ensuring consistent strength and flexibility. This longevity is crucial for mooring operations, as it minimizes the frequency of replacement and maintenance, thereby improving efficiency in port and at sea. The enhanced durability also contributes to safety by reducing the likelihood of sudden failures due to environmental stressors. Additionally, these coatings are designed to maintain their integrity across a wide range of temperatures and salinities, ensuring consistent performance in diverse maritime conditions. As a result, the use of UV-resistant marine rope plays a pivotal role in maintaining mooring systems’ operational reliability, which is paramount for securing vessels safely and efficiently in dynamic marine environments.

The Importance of Chemical Resistance in Marine Rope Coatings

In marine environments, the durability and performance of boat ropes are significantly influenced by the quality of their coatings. Rope coating technology for marine applications must prioritize chemical resistance to safeguard against the corrosive effects of seawater, which can degrade uncoated or poorly coated ropes over time. The relentless exposure to saltwater, coupled with harsh UV radiation, presents a formidable challenge for marine rope longevity. High-performance coatings that are specifically designed to be UV-resistant are crucial in preventing photodegradation, which can compromise the strength and flexibility of the rope. These coatings act as a barrier, shielding the core materials from direct sunlight, thereby extending the lifespan and maintaining the integrity of the boat rope under constant sun exposure. Additionally, the chemical resistance of these coatings ensures that they remain unaffected by the myriad of chemicals present in maritime settings, such as antifouling paints, biocides, and various contaminants found in the water. This resilience is not only critical for the safety and functionality of the rope but also for the protection of marine ecosystems, as less frequent replacement means fewer discarded ropes contributing to ocean pollution. Therefore, when selecting a marine rope, it is imperative to consider the chemical resistance properties of its coating to ensure long-term reliability and performance in the demanding marine environment.

Case Studies: Real-World Applications of UV-Resistant Marine Rope Solutions

In recent years, the development and application of UV-resistant marine rope have significantly impacted the nautical industry, particularly in boat rope technology. One pivotal case study showcases the integration of these advanced materials on luxury yachts where the rope is exposed to intense solar radiation. The UV-resistant properties of the marine rope used in this application have proven to be a game-changer, as they ensure the longevity and integrity of the rope without degradation from the sun’s rays. This has led to reduced maintenance costs and an extended lifespan for the yacht’s lines, enhancing both safety and performance at sea. Another notable application can be found in commercial fishing fleets. Traditionally reliant on robust ropes for net hauling and securing catch, these vessels often operate in areas with high UV exposure. The adoption of UV-resistant marine ropes has mitigated the frequent replacements necessitated by rope deterioration, thus increasing operational efficiency and profitability. The durability and resistance to photodegradation provided by these ropes have not only extended their useful life but also minimized environmental impact, as less waste is generated from discarded, degraded ropes. These real-world applications underscore the importance of UV-resistant marine rope technology in marine environments where sunlight plays a critical role in material performance and longevity.

In conclusion, the evolution of UV-resistant marine rope technology has significantly enhanced the durability and performance of boat ropes, leading to heightened mooring efficiency and safety in maritime operations. The chemical resistance properties of these advanced coatings ensure longevity and reliability even in the harshest marine environments. Case studies showcasing real-world applications underscore the transformative impact of this technology, demonstrating its indispensable role in the maritime sector. As such, investments in UV-resistant marine rope solutions are not only prudent but also essential for maintaining operational integrity and environmental sustainability in marine applications.