Choosing the right UV-Resistant Marine Rope is vital for maintaining the integrity and performance of your boat rope in maritime conditions. The best ropes are made from synthetic fibers like polyester or nylon that have been specially treated for UV resistance to withstand the elements without degradation. These materials not only extend the lifespan of the rope but also preserve its strength, flexibility, and resist abrasion, making them ideal for a range of maritime applications including mooring lines, sailboat rigging, dock lines, load handling with cranes, and safety equipment like lifelines and harnesses. When selecting between nylon and polyester, consider the intensity of sunlight exposure and the mechanical demands of your task; nylon, while versatile, requires regular maintenance for UV protection, whereas polyester provides superior resistance to UV rays, maintaining its properties without significant performance fluctuations. Both materials offer unique advantages, and the optimal choice hinges on balancing durability, flexibility, and UV resistance to meet your specific boat rope needs for safety and reliability at sea.

When it comes to maritime endeavors, the reliability of equipment is paramount. High-strength marine rope, a vital component for seafarers and dockworkers alike, must withstand harsh environmental conditions. This article delves into the nuances of UV-Resistant Marine Rope, exploring its essential characteristics, material options like nylon vs. polyester, and performance enhancements. Discover how each factor influences the applications and uses of marine rope across various maritime contexts to ensure safety and efficiency at sea. Whether you’re securing a vessel or anchoring a buoy, understanding the key features of marine ropes is essential for optimal performance.

- Understanding High-Strength Marine Rope: The Essentials of UV-Resistant Boat Rope

- Material Composition: Nylon vs. Polyester for Marine Ropes

- Key Features to Consider in Marine Ropes for Optimal Performance

- Applications and Uses of Marine Rope in Various Maritime Contexts

Understanding High-Strength Marine Rope: The Essentials of UV-Resistant Boat Rope

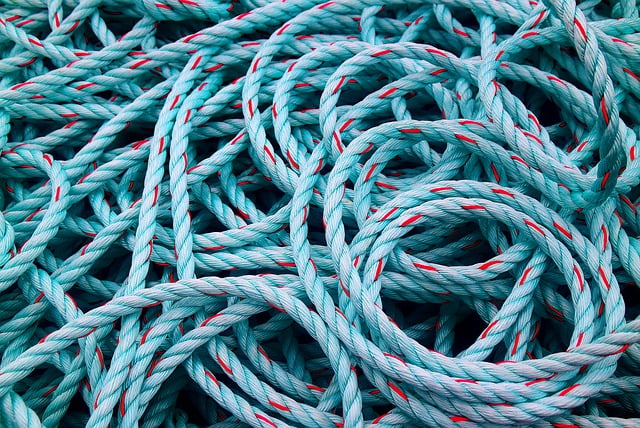

When selecting a UV-Resistant Marine Rope for your maritime needs, it’s crucial to consider the material and construction that goes into the boat rope. High-strength marine ropes are engineered to withstand the harsh marine environment, including exposure to the sun’s ultraviolet rays, which can degrade traditional ropes over time. The best UV-resistant boat ropes are typically made from synthetic fibers like polyester or nylon that have been treated to resist UV damage. These fibers not only enhance the lifespan of the rope but also maintain its strength and flexibility, ensuring reliable performance on the water.

The effectiveness of a marine rope is determined by its ability to retain strength and prevent fading or deterioration under constant sunlight exposure. A robust UV-resistant boat rope will maintain its mechanical properties, such as tensile strength and elongation, even after prolonged use in direct sunlight. Additionally, the treatment that gives these ropes their UV resistance often enhances their abrasion resistance and reduces their tendency to absorb water, which can affect both their weight and their performance. When purchasing boat rope, it’s advisable to look for products specifically labeled as ‘UV-resistant marine rope,’ indicating they have been treated to meet the demands of a nautical environment and provide longevity and reliability for your boating activities.

Material Composition: Nylon vs. Polyester for Marine Ropes

When selecting a high-strength marine rope for your maritime needs, understanding the material composition is paramount. Nylon and polyester are two common materials used in the production of UV-resistant marine ropes, each offering distinct advantages that cater to different applications.

Nylon ropes, often made from high-tenacity nylon such as Spectra or Dyneema fibers, are renowned for their strength-to-diameter ratio and abrasion resistance. They excel in environments with varying temperatures due to their minimal performance change across the spectrum. Nylon ropes are also versatile and can be used for a multitude of tasks on a vessel, from mooring lines to dinghy dock lines. However, nylon is susceptible to UV light degradation over time, necessitating regular maintenance to preserve its integrity.

In contrast, polyester ropes, which include materials like Technora or Zytel fibers, are inherently UV-resistant, making them an excellent choice for prolonged exposure to the sun’s harsh rays without significant degradation. This resistance not only ensures the longevity of the rope but also maintains its mechanical properties, offering consistent performance over time. Polyester ropes are also known for their low elongation and high resistance to abrasion and chemical damage, making them ideal for applications that require a reliable and durable rope under challenging conditions. When choosing between nylon and polyester UV-resistant marine ropes, consider the specific demands of your application, including the intensity of sunlight exposure, environmental factors, and the mechanical requirements of the task at hand. Both materials have their merits, and the best choice depends on the balance of durability, flexibility, and UV resistance you need for your boat rope.

Key Features to Consider in Marine Ropes for Optimal Performance

Applications and Uses of Marine Rope in Various Maritime Contexts

Marine ropes, often referred to as boat ropes, are pivotal components in a wide array of maritime applications, demonstrating their robustness and versatility. High-strength marine ropes, particularly those with UV-resistant properties, are essential for seafarers and maritime operations, ensuring durability and longevity even under the relentless exposure to the elements at sea. These ropes are engineered to withstand the harsh conditions of the marine environment, including the damaging effects of sunlight and saltwater, which can degrade lesser materials over time. The applications for UV-resistant marine rope are numerous, ranging from mooring lines that secure vessels in harbors to rigging on sailboats, where the strength-to-weight ratio is critical for optimal performance and safety. In addition to these, they are also employed in the construction of docks and piers, for lifting and securing heavy loads with cranes, and as part of the safety equipment on board, such as lifelines and safety harnesses. The high tensile strength of these ropes ensures that they can handle significant forces without compromising the integrity of the structure or the safety of the crew. For those investing in marine rope, it is imperative to select a rope that not only meets the specific mechanical properties required for their intended use but also one that maintains its performance characteristics over time, thus providing reliability and peace of mind on the open sea.

When selecting a high-strength marine rope for your maritime needs, it’s crucial to prioritize materials that offer both durability and resistance to environmental factors. Among the options available, UV-resistant marine rope stands out due to its ability to withstand the harsh effects of sunlight exposure without compromising on strength or performance. Whether you’re anchoring your boat, securing equipment, or engaging in water sports, the choice between nylon and polyester should be informed by your specific application needs—consider factors such as tensile strength, elongation, and abrasion resistance. By understanding the key features that influence optimal performance, such as the core construction and sheath material, you can make an informed decision that ensures safety and reliability on the water. Ultimately, the right marine rope can make all the difference in your nautical endeavors.