When choosing a marine rope for your vessel, it's essential to select one with high durability and UV resistance to withstand the harsh maritime conditions. Polyester is a preferred material due to its strong resistance to water, mildew, and UV light, which helps maintain the rope's integrity over time. A robust UV-Resistant Marine Rope should also be flexible to prevent kinks or twists, ensuring ease of handling and safety on deck. Consider the intended use—be it rigging, dock lines, or fenders—to ensure the rope meets your specific needs in terms of strength and performance. High abrasion resistance is critical for longevity, as maritime conditions can rapidly degrade standard ropes. ASTM D4535 testing confirms the best UV-Resistant Marine Ropes' ability to resist wear, with treatments that keep the rope colorfast and visible for safety. Lastly, opting for a UV-Resistant Marine Rope that is both durable against environmental factors and maintains its strength and functionality is a key decision for the longevity and safety of your vessel and crew.

When venturing out on the open sea, the reliability of your marine equipment is paramount. A pivotal component in this regard is the marine rope you choose for your vessel. This article delves into the critical aspects of selecting a UV-Resistant Marine Rope that stands the test of time and the elements. We’ll guide you through understanding the durability and material composition of ropes designed to withstand harsh UV rays, assessing strength and flexibility to match your specific boating needs, evaluating abrasion resistance, and considering color choices for optimal visibility. Additionally, we’ll explore how environmental factors like moisture and salt exposure influence your selection process. Armed with this knowledge, you can confidently navigate the market and select a boat rope that ensures safety and longevity on your maritime journeys.

- Understanding the Durability and Material Composition of UV-Resistant Marine Rope for Boats

- Assessing the Strength and Flexibility: Choosing the Right Diameter and Type of Boat Rope for Your Needs

- The Importance of Abrasion Resistance in Marine Ropes and How to Test for It

- Color Considerations in UV-Resistant Marine Rope: Visibility and Color Fading Over Time

- Environmental Factors and Their Impact on the Selection of Boat Ropes, Including Moisture and Salt Exposure

Understanding the Durability and Material Composition of UV-Resistant Marine Rope for Boats

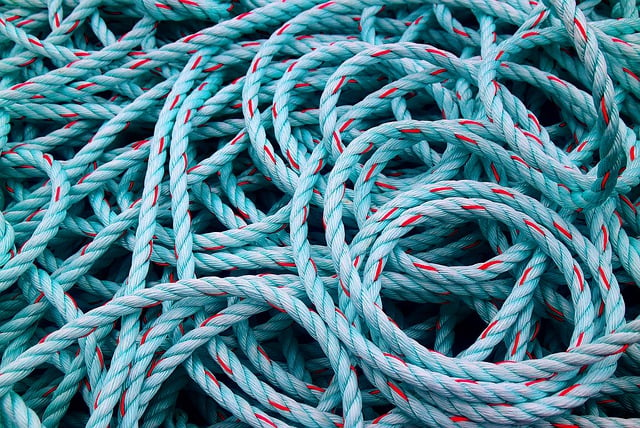

When considering the purchase of marine rope for your vessel, it’s crucial to evaluate the durability and material composition, particularly when opting for UV-resistant options. The resilience of boat rope is paramount as it endures harsh maritime conditions, including intense sunlight exposure that can degrade traditional fibers over time. UV-resistant marine ropes are engineered with additives that protect the fibers from ultraviolet radiation, which is a common cause of deterioration in nautical environments. This protection ensures the rope maintains its strength, flexibility, and appearance, even after prolonged exposure to the sun’s rays.

The material composition of marine ropes designed for UV resistance varies, with polyester being a popular choice due to its excellent resistance to water, mildew, and UV light. It’s also noteworthy that these ropes are often braided, which not only adds to their durability but also enhances their flexibility and reduces the likelihood of kinks or twists during use. When selecting a marine rope, it’s essential to consider the specific applications on your boat, such as rigging, dock lines, or fenders, and ensure that the rope you choose is up to the task. Opting for UV-resistant marine ropes from reputable manufacturers will provide peace of mind, knowing that your investment is safeguarded against the detrimental effects of sunlight exposure, ensuring your boat’s ropes remain reliable and functional throughout their lifespan.

Assessing the Strength and Flexibility: Choosing the Right Diameter and Type of Boat Rope for Your Needs

When selecting a marine rope for your nautical needs, it is imperative to consider factors that ensure both the longevity and functionality of the rope under various conditions. The strength and flexibility of UV-resistant marine rope are critical, as they directly impact safety and performance on board. Boat ropes are subject to a range of environmental stressors, including exposure to intense sunlight and saltwater, which can degrade traditional fibers over time. Opting for a UV-resistant material mitigates this risk by safeguarding the rope’s integrity against photodegradation, ensuring it maintains its strength and elasticity even after prolonged sun exposure.

Choosing the right diameter and type of boat rope is essential based on the application it will serve on your vessel. The diameter affects both the rope’s handling characteristics and its breaking strength. A larger diameter may be necessary for heavy-duty tasks where high strength is required, while a thinner rope might be more suitable for lighter uses where ease of handling is a priority. Additionally, consider the type of marine rope; polyester ropes are often preferred in saltwater environments due to their resistance to rot and abrasion, as well as their low stretch characteristics which provide consistent force application. Whether you’re mooring, tying down gear, or rigging your sails, selecting the appropriate diameter and type of UV-resistant marine rope will ensure your vessel’s systems operate optimally and safely.

The Importance of Abrasion Resistance in Marine Ropes and How to Test for It

When selecting a marine rope for your maritime needs, abrasion resistance is a critical factor to consider due to the harsh conditions ropes often face at sea. The constant exposure to saltwater, sunlight, and rough surfaces can quickly degrade standard ropes, leading to safety hazards and frequent replacements. Opting for UV-resistant marine rope enhances longevity, as these ropes are specifically designed to withstand the damaging effects of ultraviolet radiation, a common cause of wear in marine environments. Boat owners and operators must prioritize ropes that offer superior abrasion resistance to ensure the integrity of their vessels during various tasks such as mooring, towing, and hauling heavy loads.

To test for abrasion resistance, industry standards like ASTM D4535 provide a method to evaluate how well marine ropes hold up against friction and wear. This involves a controlled abrasion test where the rope is subjected to a standardized rubbing motion against an abrasive surface until a set amount of fiber has been worn away. The rate at which a rope’s fibers break down during this process determines its abrasion resistance. High-quality marine ropes, especially those labeled as UV-resistant, will exhibit less fraying and degradation after such tests, signaling their suitability for long-term use in demanding maritime applications. It is advisable to look for ropes that have passed these tests, ensuring they meet the necessary performance criteria for your intended marine application.

Color Considerations in UV-Resistant Marine Rope: Visibility and Color Fading Over Time

When selecting a boat rope for marine applications, color considerations are paramount, particularly when it comes to UV-resistant marine ropes. The visibility of the rope, especially in high UV environments, is crucial for safety and functionality. High-quality UV-resistant marine ropes are designed with colorfastness in mind to maintain their vibrancy under prolonged sun exposure. However, without regular maintenance, even the most advanced UV-resistant marine ropes can exhibit signs of fading over time. The intensity of the sun’s ultraviolet rays can lead to discoloration and weakening of the fibers if the rope is not adequately protected or chosen with the right pigments that resist fading. It’s important to opt for ropes that have been treated with UV inhibitors, which help to preserve the color and integrity of the rope, ensuring it remains visible and operational for as long as possible. The choice of color can also affect how well the rope blends into or stands out against its surroundings, influencing both aesthetics and safety. In summary, when purchasing a boat rope, especially a UV-resistant marine rope, consider the environmental factors that will affect its longevity and visibility. Opting for ropes with proven UV resistance and appropriate color pigments will not only maintain the aesthetic appeal but also ensure the safety and efficiency of your maritime activities.

Environmental Factors and Their Impact on the Selection of Boat Ropes, Including Moisture and Salt Exposure

When selecting a marine rope for your vessel, environmental factors play a pivotal role in determining the durability and longevity of the rope. Exposure to the elements, particularly moisture and salt, can rapidly degrade traditional ropes if they are not resistant to such conditions. Saltwater environments, where sailboats and other marine vessels frequently operate, pose a unique challenge due to the corrosive nature of salt. It’s crucial to opt for boat ropes that are specifically designed with UV-resistance and hydrophobic properties to combat the detrimental effects of moisture and salt exposure.

UV-resistant marine rope is engineered with advanced materials that protect against ultraviolet radiation, a significant environmental factor that can weaken and deteriorate fibers over time. The intense sunlight encountered on open waters can cause significant damage, leading to fraying and loss of strength in the rope. A robust boat rope must not only withstand the mechanical stresses of pulling and tension but also the relentless assault from the sun’s rays. Marine ropes with UV protection ensure that the rope maintains its integrity and performance throughout its lifespan, providing safety and reliability for mooring, anchoring, or any maritime application. Choosing a marine rope with these properties is not just about maintaining aesthetic appeal; it’s an investment in the safety and security of your vessel and crew.

When selecting a marine rope for your vessel, the choice extends beyond mere aesthetics; it’s about ensuring safety and reliability on the water. The durability of UV-resistant marine ropes, their abrasion resistance, and flexibility are paramount, as outlined in this article. These factors not only contribute to the longevity and performance of your boat rope but also its ability to withstand the harsh marine environment. By carefully considering the diameter and type that best suits your specific needs, you can rest assured that your investment will be protected against the elements, including UV rays and saltwater. Additionally, the color of your UV-resistant marine rope plays a critical role in visibility and maintaining its vibrancy over time. With the right marine rope, your boat’s safety and appeal are safeguarded, allowing you to navigate with confidence.