UV-Resistant Marine Rope is a critical component for maritime applications, designed to withstand the harsh marine environment and maintain its integrity over time. These ropes are engineered with advanced synthetic fibers like polyester or nylon, enhanced with UV inhibitors to prevent degradation from sunlight exposure. They offer superior strength, flexibility, and longevity, reducing the risk of discoloration, structural loss, and breakage associated with traditional natural fibers. The rope's construction includes a braided core and a protective sheath, which not only increases its elasticity and reduces kinking but also enhances its resistance to environmental factors such as saltwater, abrasion against metal hardware, and moisture. Selecting the right UV-Resistant Marine Rope ensures safety and optimal performance by resisting UV radiation, maintaining its structural integrity under tension, and enduring various tasks on board. It is essential for both commercial and recreational boat owners to invest in such ropes to guarantee longevity and consistent functionality, safeguarding against one of the most common environmental threats in maritime environments.

When venturing out on the high seas, the reliability of your marine equipment is paramount. Among these critical components, the quality of your boat rope stands out for its importance in safety and functionality. This article delves into the essential aspects of selecting a UV-Resistant Marine Rope that can withstand the harsh marine environment. We’ll explore key factors to consider when choosing the right rope, dissect the material composition that defines high-grade marine ropes, and assess their durability and strength for diverse applications. Additionally, we’ll discuss the pivotal role of UV resistance in ensuring the longevity of your rope. Finally, maintaining your marine rope through regular inspection and care will be highlighted to guarantee its optimal performance over time. With these insights, you’ll be better equipped to make an informed decision on the best UV-Resistant Marine Rope for your nautical needs.

- Understanding the Importance of Quality in UV-Resistant Marine Rope

- Key Factors to Consider When Selecting Boat Rope

- The Material Composition of High-Grade Marine Ropes

- Assessing the Durability and Strength of Marine Ropes for Various Applications

- The Role of UV Resistance in Marine Rope Longevity

- Inspecting and Maintaining Your Marine Rope to Ensure Long-Term Performance

Understanding the Importance of Quality in UV-Resistant Marine Rope

When navigating the vast waters, reliability and durability are paramount, particularly when it comes to marine ropes. A high-quality UV-resistant marine rope is essential for boat owners and maritime professionals alike due to its ability to withstand the harsh conditions of the marine environment. Exposure to sunlight can degrade traditional ropes over time, leading to potential safety hazards and equipment failure. UV-resistant marine ropes, however, are engineered with advanced fibers that resist the ultraviolet radiation responsible for degradation. This not only extends their lifespan but also ensures consistent performance, even after prolonged exposure to the sun’s rays.

Selecting a boat rope with robust UV resistance is crucial for maintaining the integrity of your vessel’s rigging and deck lines. The best marine ropes are designed to preserve their strength, elasticity, and appearance, regardless of the climate they’re exposed to. These ropes are typically made from synthetic materials like polyester or nylon that have been treated with UV inhibitors. This treatment shields the rope from discoloration and loss of structural integrity, which can occur when left untreated in direct sunlight for extended periods. Investing in a high-quality UV-resistant marine rope means you’re choosing a product that will perform reliably under all conditions, offering peace of mind for seafarers who demand the best from their equipment.

Key Factors to Consider When Selecting Boat Rope

When selecting a boat rope that will withstand the harsh marine environment, UV-resistance is paramount. Exposure to ultraviolet light can degrade natural fibers like cotton and polyester at an accelerated rate, leading to fraying, loss of strength, and eventually breakage. Opting for a marine rope specifically designed to be UV-resistant, such as those made with Spectra or Dyneema fibers, ensures longevity and reliability on the water. These high-tech materials offer superior resistance to sunlight, maintaining their integrity over time even when left in direct sunlight.

Another critical factor is the rope’s flexibility and elongation properties. A quality boat rope must have the right amount of give to absorb shock and prevent damage during routine sailing activities or unexpected events on deck. The elongation should be sufficient to handle sudden loads without snapping, yet also return to its original length without permanent deformation. Additionally, the diameter and breaking strength of the rope should align with the specific application it’s intended for, whether it’s for mooring, tying down sails, or securing gear. Always consider the environment where the rope will be used, as factors like saltwater exposure, abrasion against metal hardware, and moisture can affect performance. Opting for a marine rope that is not only UV-resistant but also durable and suitable for your boat’s specific needs is key to maintaining safety and functionality at sea.

The Material Composition of High-Grade Marine Ropes

When selecting a marine rope for your maritime needs, understanding the material composition is paramount for ensuring durability and longevity, especially under the harsh conditions presented by the marine environment. High-grade marine ropes are typically constructed from synthetic fibers that offer superior strength and resistance to degradation compared to natural fibers. Among these, UV-resistant marine ropes stand out due to their ability to withstand intense solar radiation. These ropes are often made from polyester fibers, which are known for their excellent tensile strength and resistance to chemicals and abrasion. Polyester, particularly in its UV-resistant form, retains its mechanical properties even after prolonged exposure to the sun’s rays, ensuring the rope remains stable and reliable over time.

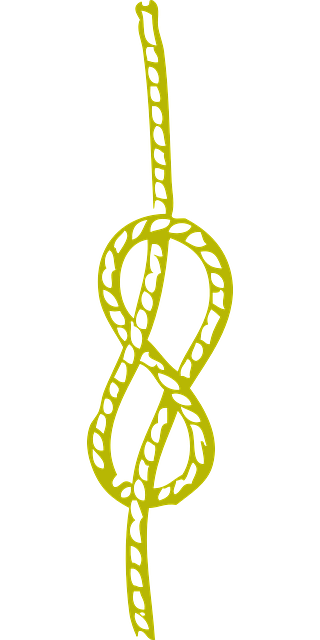

The composition of a boat rope also includes additives that enhance its performance. For instance, certain ropes are treated with ultraviolet (UV) inhibitors to prevent color fade and material degradation. This treatment is crucial for maintaining the rope’s integrity and appearance. Additionally, the core and sheath construction plays a significant role in determining the rope’s functionality. A braided core design, common in high-quality marine ropes, provides exceptional flexibility and reduces the chance of kinking or twisting. The sheath, which is often made from a different fiber to enhance abrasion resistance, protects the inner core and increases the overall durability of the rope. When purchasing a marine rope, it’s important to consider the specific requirements of your application, including the type of boat, the intended use, and the environmental conditions where the rope will be deployed. Opting for UV-resistant marine ropes ensures that your investment is protected against one of the most common threats in the maritime environment.

Assessing the Durability and Strength of Marine Ropes for Various Applications

When selecting a marine rope for your nautical needs, it’s imperative to consider the durability and strength of the material to ensure safety and longevity. High-quality UV-resistant marine ropes, such as boat ropes designed for harsh marine conditions, are engineered with advanced fibers that resist degradation from the sun’s harmful rays. This resistance is crucial, as prolonged exposure to UV light can weaken traditional ropes over time, leading to potential failure when under tension. For instance, a UV-resistant polyester marine rope not only maintains its strength but also retains flexibility and resistancy to abrasion, making it suitable for a myriad of applications on board, from mooring lines to dinghy ropes.

Strength is another pivotal aspect in choosing the right marine rope. The tensile strength of the rope must be sufficient to handle the loads it will encounter, whether it’s securing a vessel during a storm or hoisting equipment. A reliable boat rope should meet industry standards and certifications, ensuring it can withstand the pressure without breaking. Additionally, the rope should have a core that provides the necessary strength while the sheath offers protection and reduces wear from chafing against surfaces. Opting for marine ropes with a core of braided yarns or a solid core design enhances their structural integrity and performance, making them indispensable for various applications on the water.

The Role of UV Resistance in Marine Rope Longevity

When selecting a marine rope for your maritime endeavors, the integrity of the material under sunlight exposure is paramount. The durability and longevity of UV-Resistant Marine Rope are significantly influenced by its ability to withstand the harsh effects of ultraviolet radiation. Prolonged exposure to UV rays can degrade natural fibers like polyester, leading to fading, chalking, and ultimately, a reduction in strength and flexibility. This is where high-quality boat ropes excel, offering enhanced resistance to the sun’s rays thanks to advanced additives that protect against photodegradation. These additives work by absorbing the UV energy, preventing it from breaking down the polymer chains within the rope. As a result, the UV-Resistant Marine Rope maintains its mechanical properties over time, ensuring consistent performance and safety on board. When selecting marine ropes, opting for those with superior UV resistance not only extends their usable lifespan but also ensures that they continue to function optimally, even after being exposed to the elements day in and day out. This is critical for applications where reliability and longevity are non-negotiable, such as in commercial fishing operations or for leisure activities like yachting. The choice of UV-Resistant Marine Rope thus becomes a strategic decision that can significantly impact the longevity and operational efficiency of your maritime equipment.

Inspecting and Maintaining Your Marine Rope to Ensure Long-Term Performance

When navigating the maritime environment, the reliability of marine ropes cannot be overstated. A high-quality UV-resistant marine rope, such as those detailed in this article, is pivotal for ensuring safety and longevity on board. By understanding the key factors that contribute to a rope’s quality—material composition, durability, strength, and UV resistance—boat owners and professionals can make informed decisions. Regular inspection and maintenance further safeguard against deterioration, guaranteeing optimal performance in diverse applications. In essence, investing in top-tier UV-resistant marine ropes is not just a matter of preference but a critical aspect of maritime preparedness and safety.