UV-resistant marine ropes are essential for boat owners to navigate harsh outdoor conditions, including sunlight exposure, salt water, and temperature fluctuations. These challenges lead to traditional boat ropes' rapid degradation, causing issues like fraying and cracking. UV-resistant options, with specialized coatings or materials, offer enhanced durability by combating UV damage, saltwater corrosion, kinking, and wear. Investing in these ropes extends rigging lifespan, reduces accident risks, and maintains the overall integrity of a boat's marine systems.

A well-maintained marine rope is vital for the safety and performance of any watercraft. However, common mistakes in maintenance can lead to premature failure, costly repairs, and potential hazards. This article guides you through the top 5 marine rope maintenance blunders to steer clear of, emphasizing the importance of UV-resistant marine rope and effective storage practices. By understanding rope degradation and implementing best practices, boat owners can ensure their ropes stand the test of time, keeping their vessels secure and cruising smoothly.

- Understanding Marine Rope Degradation

- – Discussing the effects of sunlight, water, and environmental factors on boat ropes.

- – Importance of UV-resistant marine rope and its role in longevity.

Understanding Marine Rope Degradation

Understanding Marine Rope Degradation

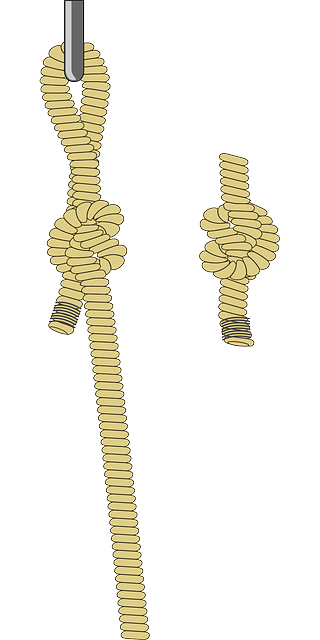

Marine ropes, including UV-resistant marine rope designed for boats, undergo unique forms of stress and exposure that significantly impact their lifespan and performance. Unlike ropes used on land, boat ropes are constantly subjected to harsh environmental conditions such as sunlight, salt water, and frequent use. These factors contribute to a process known as degradation, where the rope’s fibers break down over time, leading to weakened strength and reduced durability.

UV radiation from the sun is particularly harmful, causing the synthetic or natural fibers in marine ropes to weaken and fray. Saltwater can also accelerate this process by drawing moisture into the rope, leading to mold and mildew growth. Regular use puts strain on the rope, making it more susceptible to kinking, twisting, and wear at points of high friction, all of which contribute to premature failure. By understanding these degradation mechanisms, boat owners and operators can implement effective maintenance practices to extend the life of their marine ropes.

– Discussing the effects of sunlight, water, and environmental factors on boat ropes.

The outdoor environment presents unique challenges for marine ropes, which are constantly exposed to various elements that can impact their longevity and performance. Sunlight, in particular, is a significant contributor to the deterioration of boat ropes. UV rays from the sun can break down the chemical bonds in rope fibers over time, leading to fraying, cracking, and loss of strength. This effect is accelerated when combined with water exposure, as moisture can accelerate the aging process by softening the rope material and making it more susceptible to damage.

Other environmental factors, such as salt air and varying temperature changes, also play a role in marine rope maintenance. Saltwater can cause corrosion and weaken ropes, while fluctuating temperatures can lead to sudden expansions and contractions, putting additional strain on the fibers. To mitigate these issues, mariners should prioritize using UV-resistant marine ropes designed to withstand harsh outdoor conditions. Such ropes are crafted with special coatings or woven from durable materials that offer enhanced resistance to sunlight and environmental factors, ensuring they maintain their integrity for extended periods, even under rigorous boat handling and exposure.

– Importance of UV-resistant marine rope and its role in longevity.

UV-resistant marine ropes are an essential component in maintaining the longevity and performance of your boat’s rigging and decking. The harsh conditions faced by boats, including constant exposure to sunlight and varying water temperatures, can cause traditional ropes to degrade rapidly. UV radiation from the sun breaks down the chemical bonds in rope fibers, leading to fraying, cracking, and eventual failure.

Investing in high-quality UV-resistant marine rope is a proactive step towards ensuring the safety and reliability of your boat. These specialized ropes are engineered with additives that absorb or reflect UV rays, preventing the damage caused by sunlight. By choosing the right UV-resistant boat rope, you can extend the lifespan of your rigging, reduce the risk of accidents due to frayed or broken lines, and maintain the overall integrity of your vessel’s marine systems.

By understanding the primary causes of marine rope degradation, such as sunlight exposure and environmental factors, boaters can make informed decisions to extend the lifespan of their boat ropes. Investing in high-quality UV-resistant marine rope is a strategic move to safeguard these essential components, ensuring optimal performance and safety on the water for years to come. Regular maintenance practices, combined with the right materials, are key to avoiding common mistakes and keeping your marine ropes in top condition.